Get This Lintel Decision Wrong, and It’ll Cost You Thousands

Every builder knows this.

If you compromise on structure, you’re not just risking a callback...

You’re risking your reputation.

You go from saving a few bucks to spending thousands on legal costs.

We’ve spent 68 years backing the builders behind Australia's most reliable builds.

Here’s what every builder should know:

CON![]() CRETE OR STEEL?

CRETE OR STEEL?

Concrete lintels are great if you're going to render the lintel or wall.

Steel lintels are lighter, stronger for their weight, and easier to install, perfect for most standard builds.

Longer lengths? Go steel. If you're by the ocean, think concrete.

IF CONCRETE

Concrete Lintels are your go-to if you're going to render the lintel or wall.

✅ Make sure you install rough side down

✅ Know your span and load

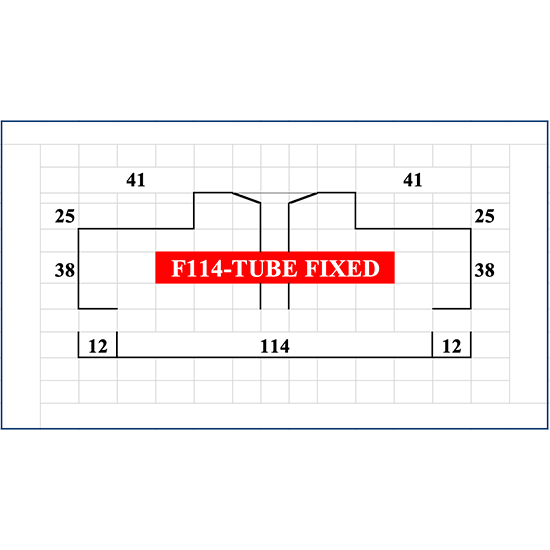

✅ For openings up to 1200mm: Minimum 100mm bearing.

✅ For openings greater than 1200mm: Minimum 150mm bearing.

IF STEEL

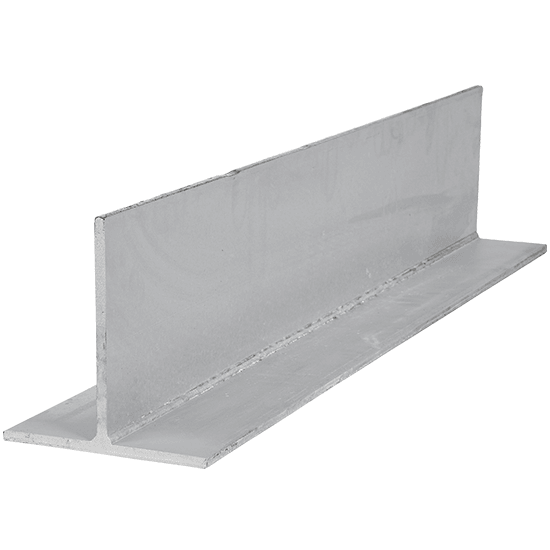

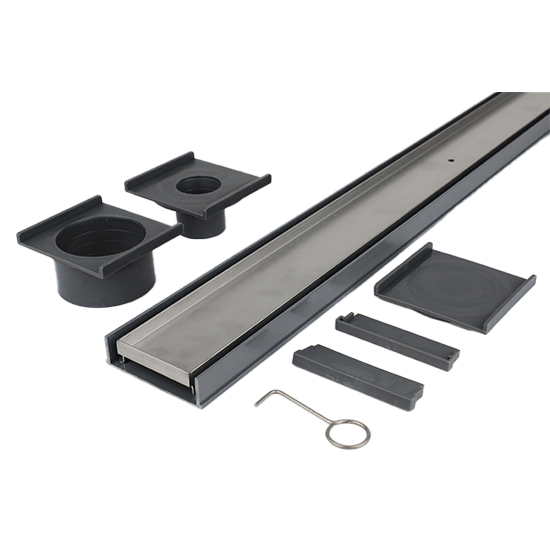

Steel lintels are easily customised and the most common option.

If it’s a face brick wall, use a Face Brick Lintel: no holes, clean finish.

If it’s being rendered, grab a Render Bar: it is slotted with holes underneath to help the render create a composite bond with the lintel.

Wrong bar = weak finish. Always match your lintel to the wall finish.

ALWAYS CONSULT YOUR ENGINEER

We’ve got the stock and we know the specs.

We take calls daily guiding builders & trade owners on next steps. Especially if Specified.

However, a certified structural engineer is the one who legally signs off on what gets used, where, and how.

Don’t guess. Engineer first, then order.

When you’re on site, you don’t want to be guessing spans or juggling weak stock.

You want product that turns up, stands up, and holds up.

We’ve got what you need — stocked and ready across all sizes, delivered anywhere in Sydney, flat rate, no matter the job.